As a large special equipment with electromechanical integration, the lift has a relatively special structure. It is delivered to the site in the form of discrete components, which are installed, commissioned and inspected before becoming a complete machine for use.

The evaluation of the quality of a lift is based on the quality of the components and the maturity of the product design, the installation process and acceptance standards, as well as the degree of maintenance after it has been put into use, each of which affects the normal use and life of the lift. Users are mainly measured by the high failure rate, followed by operational comfort and sensory effects.

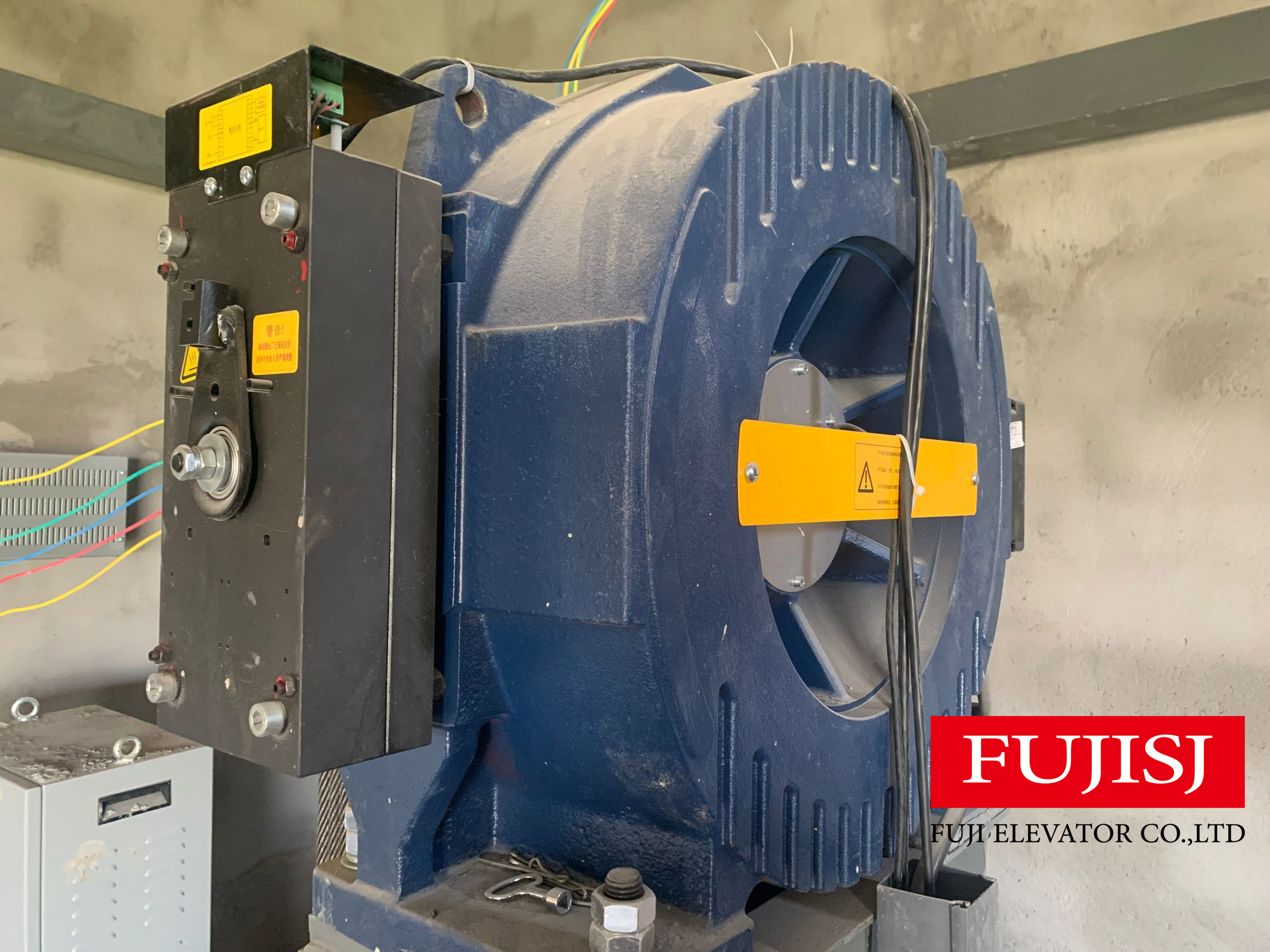

The development of traction machines has been very mature, from turbo-worm to helical gear, and then to gearless drive (including synchronous gearless, whose structure is more simplified for maintenance, greatly reducing maintenance costs and environmental pollution tends to be environmentally friendly) are all aimed at improving efficiency, improving running smoothness and reducing running noise, and later products also New requirements such as greening and environmental protection have been introduced.

The brake installed on the traction machine is the most important protection measure for the reliable stopping of the lift car. In case of poor performance, the leveling of the floor is not allowed (the frequency control system with zero speed stop has little influence), and in case of serious safety accidents such as slides.

The main causes are.

① poor lubrication of the brake arm shaft, poor lubrication of the brake suction iron core and lead to jamming, it may cause the inability to open the brake tile and burn the motor or burn the brake tile after the brake failure, there are also serious safety hazards such as open and can not be closed.

② Excessive wear of the brake tiles without timely adjustment.

③The nominal value of the brake arm tension spring does not meet the requirements (resulting in too little brake force), etc.

The speed limiter works by centrifugal force, the core of its work is the movable block, the electrical detection switch and the clamped rope weight block. Under the force of the spring of the block, the block quickly clamps the speed limiter wire rope, thus generating the pulling force required for the safety clamp, so that the safety clamp can stop the car in time, but of course, it is only effective when the car goes down and overspeeds. The counterweight safety clamp can not only protect the counterweight from falling, but also protect the car from speeding upwards. It can be seen that if the movable throwing block and the clamped rope weight shaft are not well lubricated, it is not possible to ensure safe and reliable stopping of the car or counterweight when the lift is overspeeding.

Post time: Jun-29-2022

![富吉-[LOGO]-105](https://www.fujisj.com/uploads/a78ec670.png)